About the project

For our second project, we where invited to allocated 3 weeks to explore the realm of accessories. I felt that this time limited my ability to develop a unique and interesting project. However, I would later prove myself wrong by exploring the design system of self reciprocating structures.

El presidente-350 euro.

El presidente-350 euro.

In brain storming, my initial idea sparked from necessity. Having lost a substantial amount of furniture to a flood back in Donegal months prior. My thoughts turned to our beloved hammock. How it evoked such great inspiration whilst lying in a horizontal position on those lazy days. I felt I needed to some how replicate it. From there, I began to look at what was available on the market.

Other market competition.

Other market competition.

To my dismay, most hammock and stand products available on the market where quite over priced, In my opinion. They all consisted of reasonably simplistic minimal designs, leaving plenty of room for improvement. My first act would be identifying my main competitor.

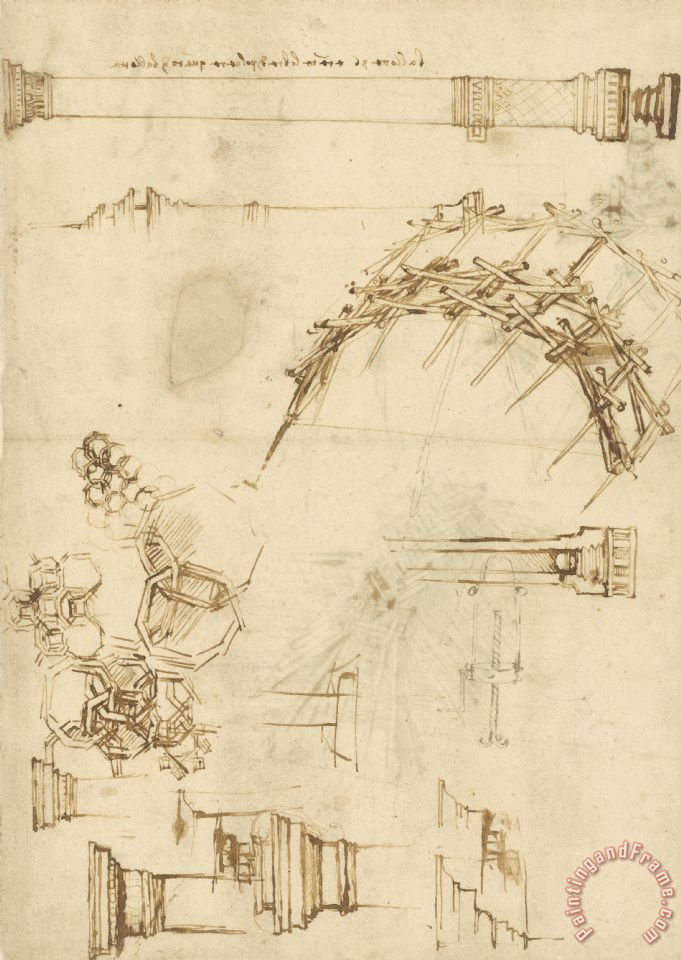

Da Vinici's depiction of this design system.

Da Vinici's depiction of this design system.

El-Presidente is an admittedly elegant and simple solution that affords ease of assembly at a hefty price. El presidente was priced at 350 euro. In its composition, I estimated its cost of materials and fabrication to be around 150. this left me in a unique position to utilize the shop bot to develop a competitive rival concept. And so I set off to to develop a rendition that provided better value for money.

Almost all of the existing products available on the market where ground based structures. In the spirit of going against the grain, I decided to invert what I had seen predominantly on the market. Hanging the hammock from the stand, as opposed to hanging it ON the stand. creating a broad new dimension of unforeseen capabilities to the concept.

I've always been fascinated by Da Vincvi's work, and decided this would be a great opportunity to study another one of his concepts. Da Vinci designed a self supporting bridge that required no nails or fixings. It can be dis-assembled to be taken with troops on the march. Intended for military use, it was envisioned that it would enable troops to cross rivers and streams quickly.

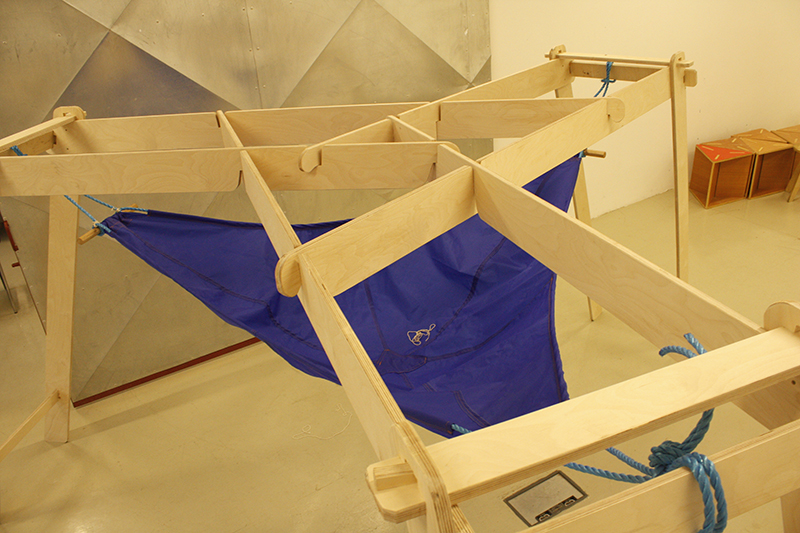

load test of early scale model

load test of early scale model

After some studying on the subject I decided to disregard its militaristic origins, and focused on using the design system to create a peaceful space to relax.

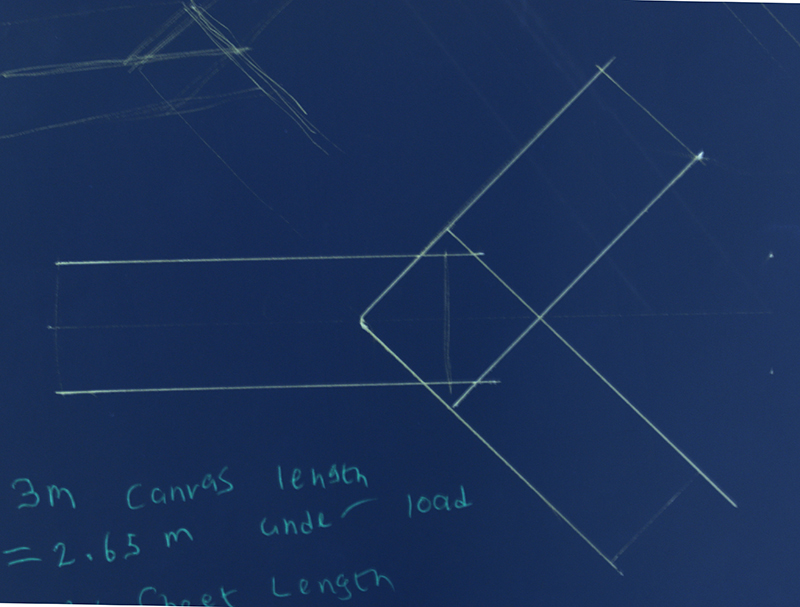

Early dimensional drawing.

Early dimensional drawing.

My first model was cut using the speedy 400. I used it to learn about the dynamic forces involved in a self supporting “Da vinci” bridge. Some interesting points where established in making this early model. It was quite a challenge to assemble, due to a lack of friction between spars. I also noted that by decreasing the distance between spars, the angle of interlinking beams increased. This would later allow me to get away with using one set of legs to attain my desired structure height.

With some basic dynamics on the system understood, I decided to address some of the more fundamental aspects of its need to act a hammock stand. Stability would become a defining factor, As I had previously learned from the last models inherent instability. I felt the best way to approach this might be using 3 sets of legs interlinked in the center.

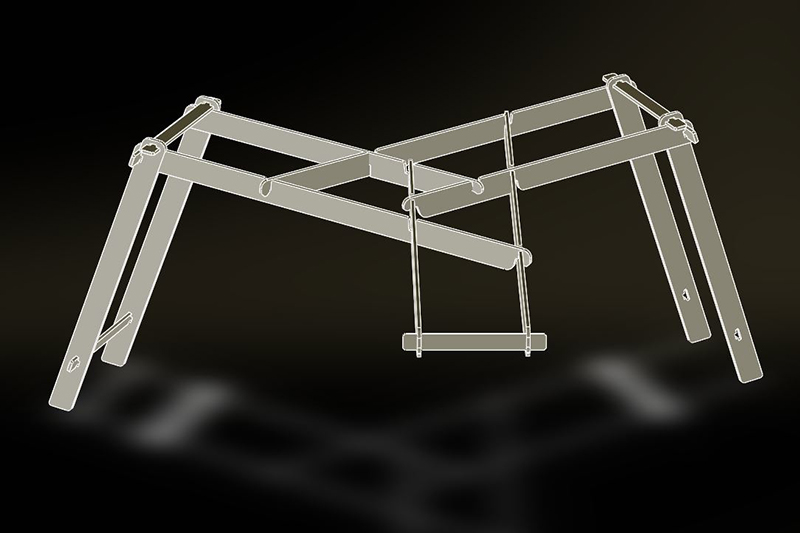

My alternative composition.

My alternative composition.

After some consideration, I set out to draw two versions of how I could imagine it working. The first had one set of legs elongated providing a longer overall hammock area, ideal for a single person. My second approach was to mimic sacred geometry, Creating a structure that shared the kinetic load evenly throughout all its components. I made a prototype to test my second plan and after minor alterations it worked.

I took my final drawing and set out to render it in solidworks. once satisfied with the scale, I extruded all the components in the drawing and gave them their corresponding profile cuts. Consideration was made after the previous small scale model. I decided to increase all the tolerances to ease the assembly process. And began laying out my parts sheet. Moving to the shop bot the following day.

With my parts cut out I assembled the first full scale prototype in the fab labs exhibition space. I was surprised with how easy it was to assemble. The only thing missing was a hammock. Happy with its proportions, I took some measurements to gauge the anticipated material surface area needed. Utilizing a juki, industrial sowing machine And an experienced friend. We set out to teach me how to operate the machine. 2 days later and the hammock was complete.

In conclusion, I still feel an urge to return to this project for a final rendition some day. The concept I have made at the fab lab will be used. I intend to buy more material and give it a canopy. I hope to explore the possibilities of using this structure as a micro living space. I think my next field of study may lead me to traditional Yurts.

Class mate Ben testing my concept.

Class mate Ben testing my concept.

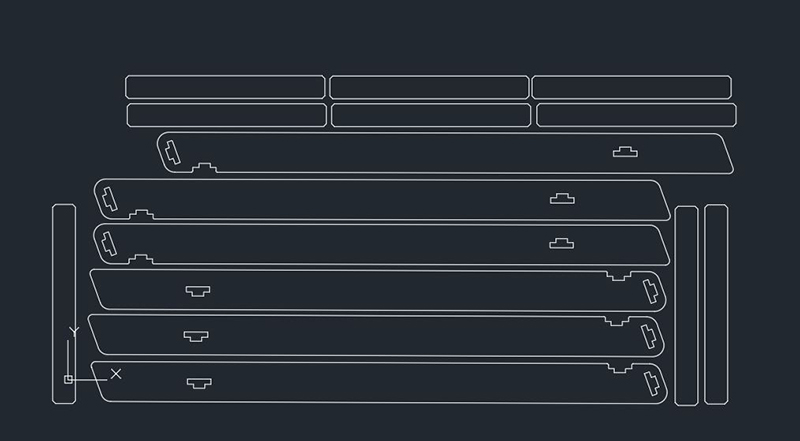

One of my final cutting sheets.

One of my final cutting sheets.