vacuum powered screen printing press. solving a problem highlighted by Billy

Project Description

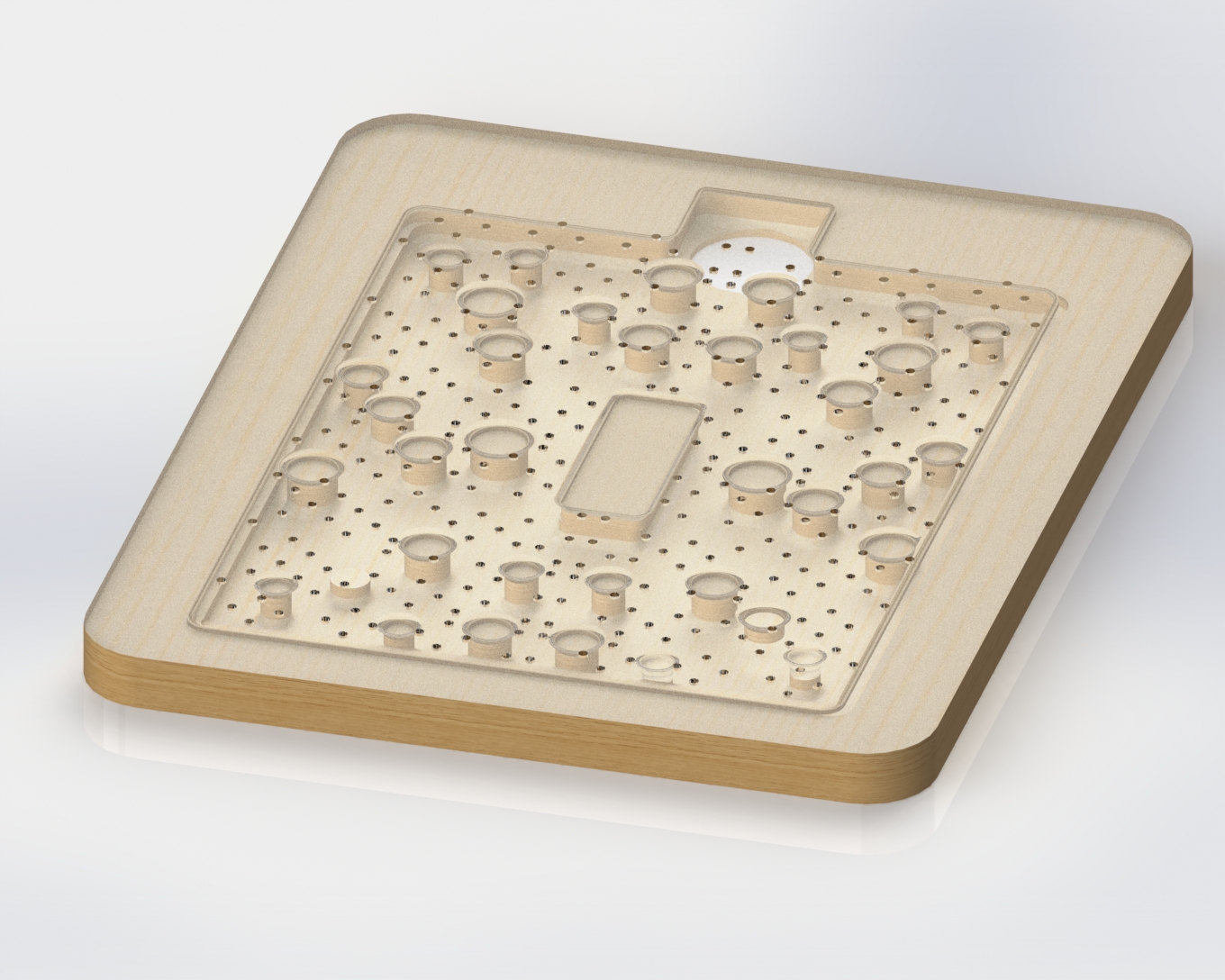

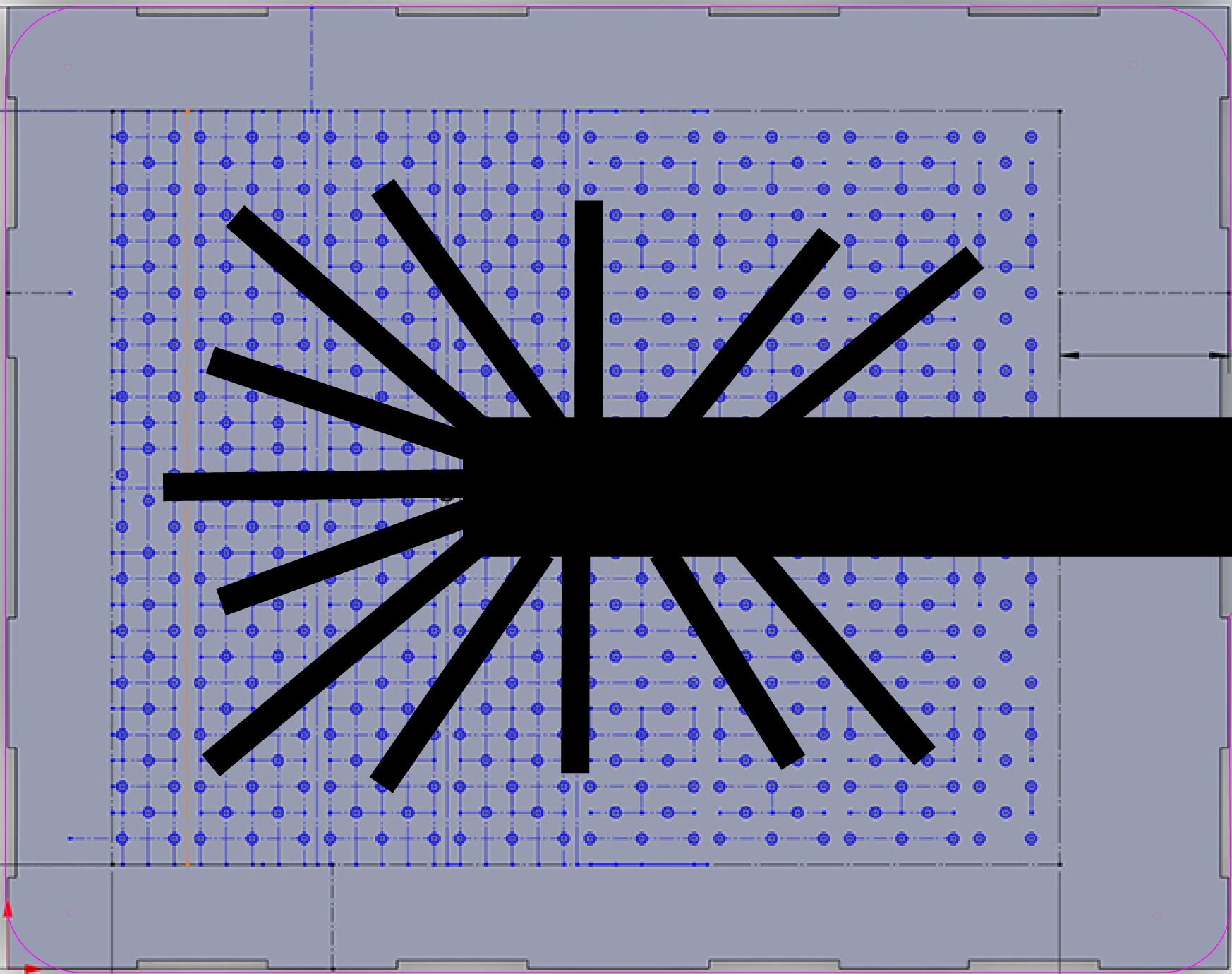

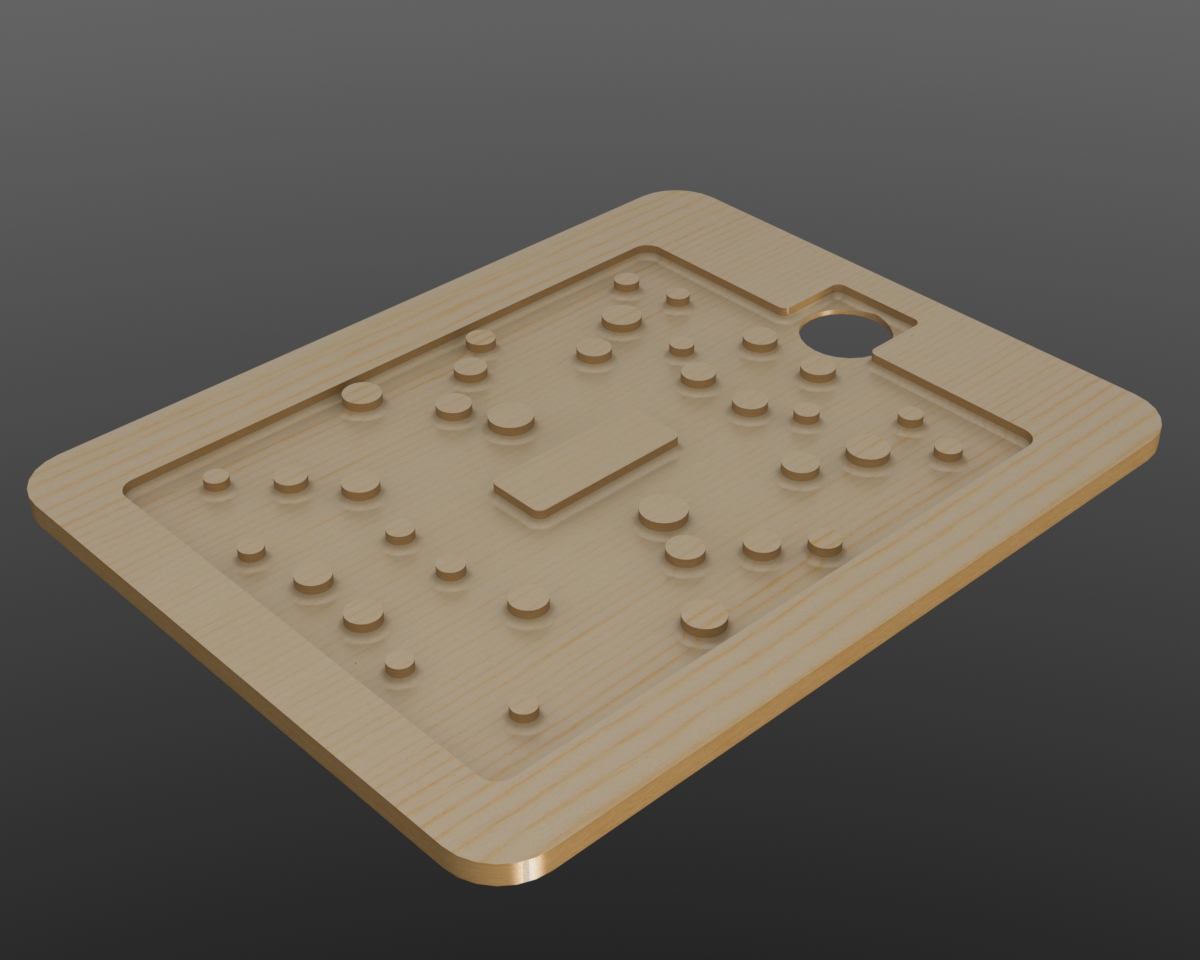

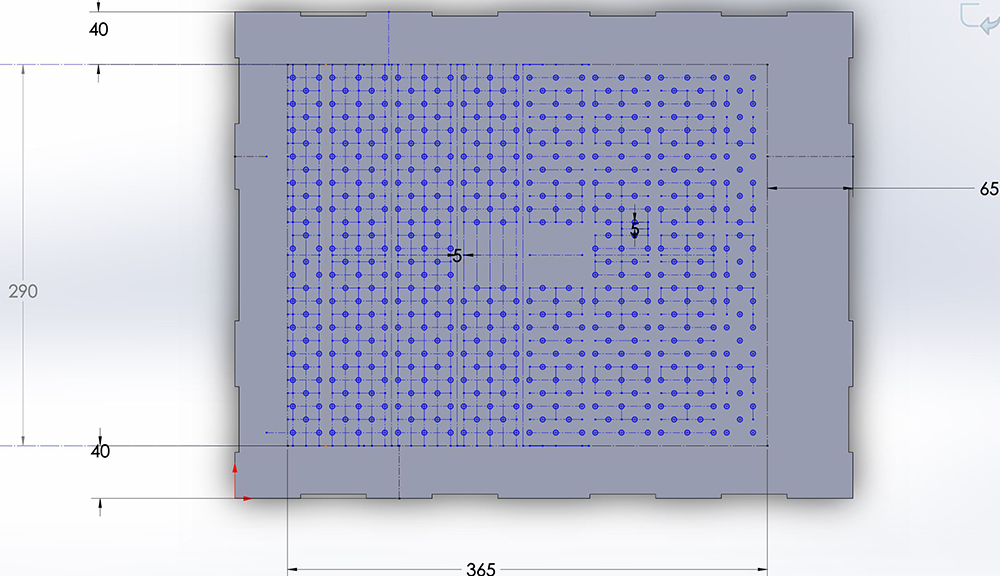

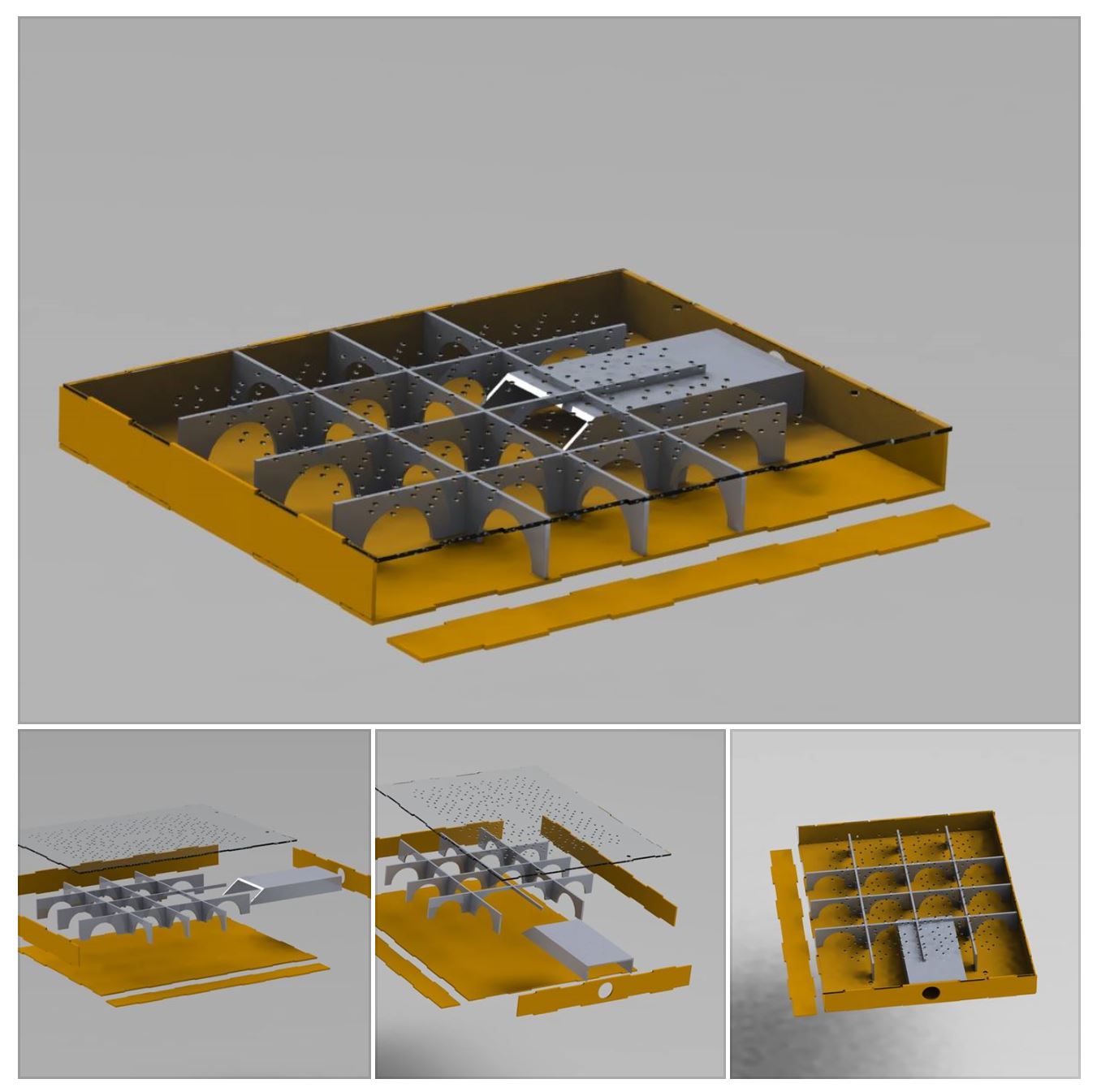

This group project was taken on by four student at the start of the semester. However, by the end of the course only two remained. Billy and I produced all of the work for this concept and as a result I feel it may be lacking in some ways. The plan was to produce a vacuum table screen printing press. Billy highlighted an issue found in the screen printing presses he has owned, stating that the page would often slip. We set out to make a cheap and easy to produce alternative. In making one of these vacuum screen printing presses, we realized that the concept is viable. Acting exactly as proposed. I personally produced and rendered two different concepts proposed for this project. These designs where an integral part of visual communication through out the process. My first design was rather simple in its composition and very closely mirrors bills final production. The second design I rendered was created upon Eamons recommendation. He proposed that we remove material from the inside faces of two pieces of MDF and glued them together, creating a hollow channel for the vacuum. We later realized that this lacked the depth to affix a vacuum hose. We also realized that the thinner sheets of MDF where significantly cheaper than the thicker sheets of MDF proposed for use in Eamons design idea. With this realization we reverted back to box concept, with billy producing the final working piece.

Project Details

- Concept utilizes the suction from a vacuum to keep page positioned during screening printing process.

- this could easily be addapted to create a vaccum form. An idea worth revisiting

- i contributed to 2 of our concepts. Developing solidworks renderings for both.

group page.

check out the link to our group page here.